NAAC-Accredited 'A++' - Grade 2(f) & 12(B) status (UGC) |ISO

9001:2015 Certified | FIST Funded (DST) SIRO(DSIR)

Facilities

Computer systems

- DELL / Lenovo - 8GB Ram / 1Tb HD / Intel Core i7 Gen/ 2Gb GC/ Windows 10 64 bit OS – 60 nos.

HARDWARE

- FANUC CNC LATHE LT-16 ACE DESIGNERS

- ELECTRONICA WIRECUT

- 3D PRINTER

SOFTWARE

- 3D EXPERIENCE – CATIA

- Pro/E WILDFIRE

- SOLID WORKS

- ANSYS

- CADEM

- Make-Shimadzu-Japan.

- Model-HMV-G3IST(Auto Reading with Electric Turret)

- Load – 0.1 g to 2000 g (2 Kg)

- Vickers Diamond Intender

- Sample max height – 100 mm

- Sample surface- Flat, Cylinder and Spherical

| Make | Fritsch, Germany |

| Model | Planetary Mono Mill classic line Pulverisette – 6 |

| Maximum sample quantity | 225 ml |

| Maximum Feed Size | 10mm |

| Final Fineness | 20µm |

| Rotational speed | 100-600 rpm |

| Tungsten carbide Grinding bowl 80ml volume | Minimum fill : 1ml Maximum fill : 30ml |

| Tungsten carbide Grinding balls | 30 balls of 10mm diameter |

| Tempered steel Grinding bowl 250 ml | Minimum fill : 30ml Maximum fill : 125ml |

| Tempered steel Grinding balls | 50 balls of 10mm diameter |

| Tempered steel Grinding balls | 15 balls of 20mm diameter |

| Tempered steel Grinding balls | 06 balls of 30mm diameter |

| Dimensions | 500 x 370 x 530 mm (height x width x depth) |

| Weight | 67 kg |

|

|

| Make | Dynatronix, USA |

| Model | Micro Star Pulse Series DPR 20-30-100 Power Supply |

| Input power | 110 - 120 VAC Single Phase 50-60hz |

| Output rating | 0-20V, 30A avg, 100A peak |

| Pulsed output wave shape | Bi-polar square wave -50µec rise max, 50µsec fall max |

| Output resolution | 20.0V / 99.9A |

| Meter resolution | 20.0V / 30.0A |

| Size | 432mm X 222mm X 584mm |

| Weight | 18.4kg |

|

|

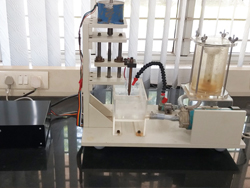

| Make | Designed in-house and fabricated locally |

| Model | Specially ordered for silver plating |

| Construction | Steel frame |

| Acrylic tank size | 250 x 250 x 250mm |

| Tank capacity (max) | 15 litres |

| Pump | Magnetic type |

| Pump capacity | 30 lit/hr |

| Filter | 125 mm cartridge type |

| Cathode movement (stroke length) | 75mm |

|

|

| Make | Olympus, Japan |

| Model | BX41M-N22MB Upright Metallurgical Microscope |

| Optical system | UIS ( Universal Infinity System) |

| Focusing system full stroke | 25mm |

| Trinocular tube | U-TR30-2 |

| Sextuple revolving nosepiece | U-D6RE |

| Mechanical stage with right-hand drive control | U-SVRM |

| M Plan Achromat objective | MPLN10X, MPLN20X, MPLN50X & MPLN100X |

| Wide field eyepiece | WH10X and WH15X |

| Magnification (maximum) | 1500X |

|

|

| Image acquisition system | |

| Make | Moticam |

| Model | 1.3-Megapixel CMOS Digital Camera |

| Image device | CMOS ½” |

| Resolution | 1.3-Megapixel, 1280 x 1024 pixels |

| Pixel pitch | 5.2µm x 5.2µm |

| Maximum frame rate | 15 fps @ 1280 x 1024 |

| Dynamic range | 54 dB S/N |

| Voltage | DC 5V ± 5% |

| Power consumption | 1W |

| Operating current | 200 mA |

| Make | Sivasakthy Electrical Services, Salem |

| Model | Specially ordered for Micro machining |

| Pump | Magnetic type |

| Pump | 16 -18 Lit / min |

| Motor | Stepper motor |

| Motor resolution | 1.8°/ step |

| Lead screw | 30 teeth per inch for 75mm |

| Filter | 5 micron cartridge |

| Acrylic tank size | 200 X 100 X 80 mm |

| Tank Capacity (max) | 1.6 liters |

| Tool movement per revolution of motor | 0.8467 mm |

| Maximum tool movement | 75 mm |

|

|

| Thermal evaporator unit is a versatile laboratory coating unit for thin film applications with facilities for Thermal evaporation, glow discharge cleaning. This unit offered with accessories like Substrate Heating and work holder to meet the specific requirements. It is an ideal unit for thin film coatings in Research. The coating unit & and its chamber gadgetries are manufactured out of high vacuum compatible materials & components. | |

| Specification: | |

| Vaccum Chamber & Pump: |

|

| L.T POWER SUPPLY: | One 200 amps power supplies capable of delivering 200 amps at 10 volts, 100 amps at 20volts |

| H.T POWER SUPPLY: | A 5000 volts DC Open circuit, 3500 volts at 50 mA high reactance type transformer and solid state bridge rectifier |

| SUBSTRATE HEATER: | Substrate heater to heat the substrate from R.T to 250 deg. C. Temperature measurement using ‘K’ type thermocouple. |

| UTILITIES : | The following utilities are to be provided by the user for operation of the equipment. POWER: 220 V.A.C. 50Hz 1 phase. WATER: 4-5 lit/min. at 20°C at the inlet at 2 Kg/cm2 pressure LIQUID NITROGEN: 4-5 ltrs.of liquid nitrogen to be poured to operate the system for 5working hours. |

|

|

| Details | CVD coating process can produce fine coatings through their process parameters like plating condition, bath composition, etc. Coatings obtained from this process are also porosity free and it incurs low cost and is simple in operation. |

|

|