NAAC-Accredited 'A' - Grade 2(f) & 12(B) status (UGC) |ISO

9001:2015 Certified | FIST Funded (DST) SIRO(DSIR)

Projects

External Funded Projects

| Sl.No | Details of Project | Grant Details |

|---|---|---|

| 1 | Modification of Industrial Grade Sewing Machine to make it user suitable for differently abled persons | DST – Instrument development program (2016-2018) |

| 2 | Women Technology Park – (WTP) Sewing machine for differently abled women | DST – SEED – WTP Grant (2017-2020) |

| 3 | Design, Development and Optimization of a Moisture Management Simulator to Quantify Moisture Transfer in Active Sportswear under various Deformations using Thermal Image Processing | Institute of Engineers India (IEI), New Delhi (2017-2018) |

| 4 | Design and Development of Sensor Based Industrial Over- Lock Sewing Machine for Orthopedically Handicapped People | Institute of Engineers India (IEI), New Delhi (2019-2021) |

| 5 | Intelligent Image analysis for textile fabric defect identification | DST Grant – FIST Project (2017-2022) |

| 6 | Experimental Study on Performance Behaviour of RC Beam Using High Performance Textile Reinforcement for Precast Construction | Institute of Engineers India (IEI), New Delhi (2016-2018) |

| 7 | "Design and development of a Noval device for Textile looms to eliminate the false selvedge and reduce the associated yarn wastage". | DST - Technology Development Transfer – Device |

| 8 | Recycling of pre and post consumers garment waste | “SIDBI” fund |

| 9 | Study and design development of cost-effective semi-automatic sanitary napkin machine | “MSME” fund |

| 10 | National Technical Textiles Mission |

In-House R&D Projects

- Hot Air Seam Sealing Machine (For making PPE coverall kit)

- Nano Finished double layer protection face Mask for covid pandemic

- New instrument used to study the effect of cyclic stress on the transverse wicking behaviour of cotton/lycra knitted fabrics

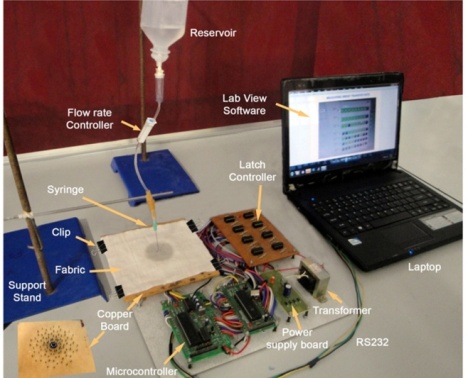

- Sweat transfer tester used to study the dynamic liquid spread behaviour of multi weave fabric

- Sweat evaporation device used to evaluate the sweat evaporation characteristics

- Colour sensor based vertical wicking instrument to measure movement of water in inter-fibre capillaries of textile fabrics

- Durable mosquito repellent finish on textile products as “ahimsa” process

- Single drop absorbency tester to test the water absorbency time of any fabric

- Multi-layer wicking tester for textile fabrics

SEED Fund R&D Projects

- Banana SAP Extraction

- Durable mosquito repellent finish on textile products

- Development of smart socks for infants to monitor vital parameters

- Modification Of Button Sewing Machine For Loco motor Disabled person

- Development Of Microbial Resistance Dish wash Scrubber From Natural Fibres

EXTERNAL R & D PROJECTS

To Eliminate the false selvedge formation and reduce the associated yarn waste and save production cost DST –TDP –DDP Grant

Dr.M.Rameshkumar, Mr.S.S.Suresh

To Recycle textile waste material and produce useful utility products/ business - SIDBI- SWAVALAMBAM FUND

Dr.D.Raja, Mr.S.S.Suresh

Completed Projects

- MOP yarn production in association with M/s ELDATEX, Salem by Dr. C.V. Koushik, Prof. G. Gunasekaran and Dr. C. Prakash with a financial assistance of Rs. 1,20,000.

- Design and Development of cyclic stress instrument used to study the dynamic liquid spread behavior of cotton/ lycra fabric in association with Spinwell Valliappa Pvt. Ltd., Benagaluru by Dr. D. Raja, Prof. G. Gunasekaran, Prof. A. Jebastin Rajwin and Prof. R. Ganesh Kumar with a financial assistance of Rs.1,25,000/-.

- Design and Development of sweat transfer tester used to measure sweat transfer behaviour of multi design fabrics in association with Spinwell Valliappa Pvt. Ltd., Benagaluru by Dr. D. Raja, Prof. G. Gunasekaran, Prof. A. Jebastin Rajwin and Prof. R. Ganesh Kumar with a financial assistance of Rs.1,30,000/-.

- Estimation and improvement of needle running time in apparel industry by novel instrument in association with Spinwell Valliappa Pvt. Ltd., Benagaluru by Prof. A. Jebastin Rajwin, Dr. M. Ramesh Kumar and Prof. S. Keerthana with a financial assistance of Rs.1,35,000/-.

- Novel test method for evaluating sweat evaporation characteristics of woven and knitted fabrics in association with Spinwell Valliappa Pvt. Ltd., Benagaluru by Dr. D. Raja, Prof. C. Prakash, Prof. K. Mani and Prof. S. Priyalatha with a financial assistance of Rs.1,20,000/-.

- Automation in single needle lock stitch machine for collar fabrication in association with Sona Valliappa Textile Mills Pvt. Ltd., Salem by Dr. D. Raja, Dr. C. Prakash, Prof. S. Chinnadurai and Prof. D. Vasanth Kumar with a financial assistance of Rs.1,25,000/-.

- Fabrication of single needle lock stitch machine for a differently abled person ester in association with Sona Valliappa Textile Mills Pvt. Ltd., Salem by Dr. D. Raja, Prof. K. Mani, Prof. Gunasekaran and Prof. A. Jebastin Rajwin and Prof. R. Ganesh Kumar with a financial assistance of Rs.1,50,000/-.

Ongoing Projects

Area 1: Functional Textiles – Using PCM and Graphite powder

- To investigate the Functional properties of Textile Materials Using PCM

- To investigate the comfort properties of Textile Materials Using Graphite powder

Area 2: Textile Reinforced Concrete using various textile structures

To improve the concrete performance properties using various textile structures.

Area 3: Surface Modification of Textile Materials Using Banana Leaf Extraction

To enhance the comfort properties of textile materials using banana leaf extraction.

Area 4: Design and development of plasma treated textile material to enhance the comfort properties

Design and development of plasma treated textile material to enhance the thermal comfort, tactile comfort and physiological comfort

Area 5: Artificial Intelligence Application in Textile and Apparel Industry

To develop Neural Network models for forecasting parameters of textile apparel products that can be used by relevant industry

Area 6: Design and development of modified SNLS machine

To develop the attachment for auto feeding of material in single needle lock stitch (SNLS) machine and study for various other automations

Area 7: Design and development of novel test methods and devices used to measure the moisture management characteristics of textile fabric

To design and develop new test methods and devices to measure the sweat absorbency, spreading, traverse wicking and evaporation characteristics of textile fabric objectively, both in static and dynamic condition

Academic Research Projects

- Design and development of transverse wicking measurement device and analysis of dynamic liquid transfer behaviour of the fabrics

- A study of yarn and fabric properties of bamboo cotton blends

- Study of the effect of herbal and charcoal treatments on functional properties of fabrics