NAAC-Accredited 'A' - Grade 2(f) & 12(B) status (UGC) |ISO

9001:2015 Certified | FIST Funded (DST) SIRO(DSIR)

Products / Processes Developed

| Sl.No | Instrument / Product Developed | Grant Fund Received |

|---|---|---|

| 1 |  PI : Dr.D.Raja PI : Dr.D.RajaCo-PI : Mr.K.Mani, Dr.G.Gunasekaran |

Modification of Industrial Grade Sewing Machine to make it user suitable for differently abled persons DST – Instrument development program (2016-2018) Purpose : Modified sewing machine suitable for differently abled persons Benefit: Economy development and Livelihood development |

| 2. |  PI : Dr.R.Malathy Co-PI : Dr.D.Raja, Mr.K.Mani |

Women technology park – (WTP) Sewing machine for differently abled women DST – SEED – WTP Rs.18.14 Lakh Grant (2017-2020) Purpose : Assistive device for sewing machine suitable for differently abled women Benefit: Economy development and Livelihood development |

| 3. |  Scholar: Mrs.S.Priyalatha Scholar: Mrs.S.PriyalathaGuide: Dr.D.Raja |

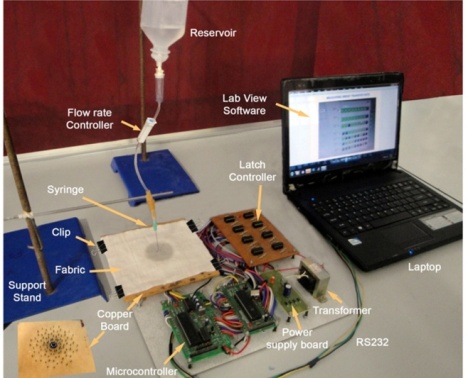

Design, Development and Optimization of a Moisture Management Simulator to Quantify Moisture Transfer in Active Sportswear under various Deformations using Thermal Image Processing Institute of Engineers India (IEI), New Delhi (2017-2018) Purpose : Evaluation of wicking characteristics of sports textile fabric under dynamic conditions Benefit: Textile fabric testing instrument using CMOS camera and micro climate chamber to simulate various values of temperature controlled environments |

| 4. |  Scholar: Mr.S.S.Suresh Guide: Dr.D.Raja |

Design and Development of Sensor Based Industrial Over- Lock Sewing Machine for Orthopedically Handicapped People Institute of Engineers India (IEI), New Delhi (2019-2021) Purpose : Assistive device for Over-lock sewing machine suitable for orthopedically handicapped persons Benefit: Economy development and Livelihood development |

| 5. |  PI : Dr.D.Raja |

Intelligent Image analysis for textile fabric defect identification DST Grant – FIST Project (2017-2022) Purpose : To detect the defects in fabric material using online digital image input/analysis/processing methodology Benefit: Accuracy in defect detection, time saving method, Human errors can be eliminated, increased production capacity. |

| 6. |  Scholar: Mr.S.Paramasivam Guide: Dr.M.Ramesh Kumar, DR.R.Malathy |

Experimental Study on Performance Behavior of RC Beam Using High Performance Textile Reinforcement for Precast Construction Institute of Engineers India (IEI), New Delhi (2016-2018) Purpose : The reinforcement with warp knit synthetic textile fabrics improve the performance properties in terms of flexural strength, first crack load, ductility factor, energy absorption capacity Benefit: Improved strength and ductility factor |

IN-HOUSE R & D PROJECTS

| 1 |  |

Hot Air Seam Sealing Machine (For making PPE coverall kit) |

| 2 |  |

Nano Finished face Mask for covid pandemic |

| 3 |  |

New instrument used to study the effect of cyclic stress on the transverse wicking behaviour of cotton/lycra knitted fabrics |

| 4 |  |

Sweat transfer tester used to study the dynamic liquid spread beahaviour of multi weave fabric |

| 5 |  |

Sweat evaporation device used to evaluate the sweat evaporation characteristics |

| 6 |  |

Color sensor based vertical wicking instrument to measure movement of water in inter-fibre capillaries of textile fabrics |

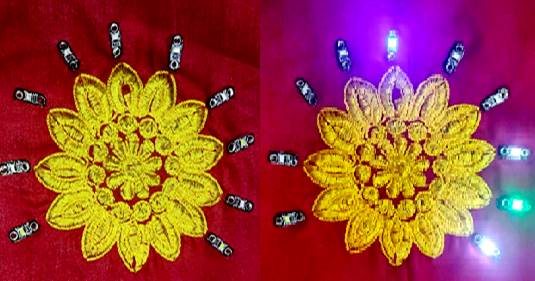

WEARABLE TECHNOLOGY PROJECTS

Textile Strain Sensor to measure muscle articulation and function

Textile Sensor to monitor hand touch/pressure

Smart Aesthetic Embroidered LED garment

Printed Textile Sensor Pattern to Measure Temperature

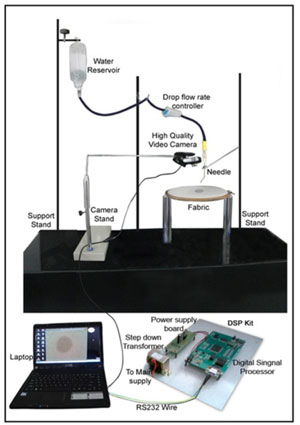

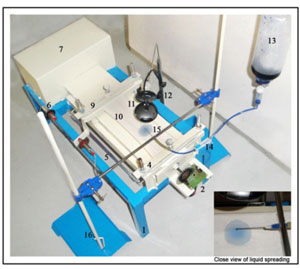

- Novel method to measure the water spreading area on the fabric

- New technique used to measure water spreading area on the fabric by image analysis method

- Novel test method used to measure water spreading area on the fabric by embedded image analysis technique using digital signal processor.

- Design and development of new instrument used to study the effect of cyclic stress on the transverse wicking behaviour of cotton/lycra knitted fabrics

- Design and development of new instrument used to study the effect of cyclic loading on the transverse wicking behaviour of cotton/lycra knitted fabrics

- Design and Development of sweat transfer tester used to study the dynamic liquid spread beahaviour of multi weave fabric.

- Design and development of sweat evaporation device used to evaluate the sweat evaporation characteristics.

- Development of yarns and fabrics using bamboo and blends

- Novel process of application of Bamboo and Neem charcoal micro particles, to study its effect on the functional properties of woven fabrics.