Dr.D.Raja, M.Tech., Ph.D

Professor & HOD,

Department of Fashion Technology,

Sona College of Technology,

Salem

Ph: +91 - 427 - 4099999 / Ext: 835

Email: rajad@sonatech.ac.in

- ACADEMIC BACKGROUND

- SUBJECTS TAUGHT / ABLE TO TEACH (UG)

- TEACHING EXPERIENCE

- INDUSTRIAL EXPERIENCE

- R & D AND FDP FUNDS RECEIVED FROM DST/AICTE/IEI

- RESEARCH PUBLICATIONS IN INTERNATIONAL JOURNALS (WITH IMPACT FACTOR)

- RESEARCH PUBLICATIONS IN INTERNATIONAL CONFERENCES

- AICTE STAFF DEVELOPMENT PROGRAME ORGANIZED AS JOINT COORDINATOR

- STAFF TRAINING ATTENDED

- LECTURE DELIVERED AS RESOURCE PERSON

- MEMBERSHIP OF THE PROFESSIONAL BODIES

- PATENT GRANTED

- PATENT APPLIED

- AWARD RECEIVED/HONOR

- REVIEWER OF THE JOURNALS

- CITATION INDICES

- CONSULTANCY WORK

- COMPLETED RESEARCH WORK

ACADEMIC BACKGROUND

| Qualification | Field of Specialization | Year of passing | Class | School/ College / University |

|---|---|---|---|---|

| Ph.D | Textile Technology | 2013 | Highly Commended | Anna University, Chennai. |

| M.Tech | Textile Chemistry | 2008 | I Class with Distinction | Anna University, Chennai. |

| AMIE | Textile Engineering | 2006 | I Class | The Institution of Engineers (India), Calcutta |

| ADCA | Computer Application | 1999 | I Class | DOEACC – New Delhi |

| Diploma | Textile Technology | 1994 | I Class with Distinction | Thiayagarajar Polytechnic College, Salem |

Title of the PhD thesis

DESIGN AND DEVELOPMENT OF TRANSVERSE WICKING MEASUREMENT DEVICE AND ANALYSIS OF DYNAMIC LIQUID TRANSFER BEHAVIOUR OF THE FABRICS

Areas of specialization

- Instrument Development For Textile/ Garment Application

- Wearable Textiles

- Fabric Moisture Management

- Clothing comfort - Sweat transfer/evaporation rate measurement, Dynamic Liquid spread behavior measurement

SUBJECTS TAUGHT / ABLE TO TEACH (UG)

- Fundamentals of Fabric Manufacture

- Chemical Processing of Textiles and Garments

- Computer Application in Garment Industry

- Apparel Costing

- Management of Apparel Units

- Men’s and Children’s wear

- Supply Chain Management

- Apparel Production Planning and Control

- Industrial Engineering in Garment Production

- Clothing Size and Fit

- Testing and Quality Control of Textiles and Apparel

- C/C++ Programming

TEACHING EXPERIENCE

| Organization | Designation | Period of Service | No of Years | |

|---|---|---|---|---|

| From | To | |||

| Sona College of Technology Salem – 636005 | Professor | Feb 2019 | Till Date | |

| Sona College of Technology Salem – 636005 | Associate Professor | Oct’2013 | Jan 2019 | 5 Yrs 4 Months |

| Sona College of Technology Salem – 636005 | Senior Assistant Professor | Nov’ 2008 | Sep’ 2013 | 4 Yrs 10 Months |

| Thiagarajar Polytechnic College Technology. | Lecturer | Oct’ 1995 | Jun’ 2003 | 7 Yrs 8 Months |

INDUSTRIAL EXPERIENCE

| Organization | Designation | Period of Service | No of Years | |

|---|---|---|---|---|

| From | To | |||

| Golden Spinning Mills, Salem | Maintenance supervisor | Jul’ 1994 | Jul’ 1995 | 1 years |

| Vertex Fabrics (P) Ltd., Avinashi. | Junior Merchandiser | Jul’ 2003 | Jun’ 2006 | 3 years |

| Vertex Fabrics (P) Ltd., Avinashi. | Merchandiser | Jul’ 2008 | Nov’2008 | 4 Months |

R & D AND FDP FUNDS RECEIVED FROM DST/AICTE/IEI

| S. No. | Name of the Funding Agency (AICTE / Others) | Name of the Scheme | Name of PI | Name of Co-PI | Programme Title | Duration | |

|---|---|---|---|---|---|---|---|

| From | To | ||||||

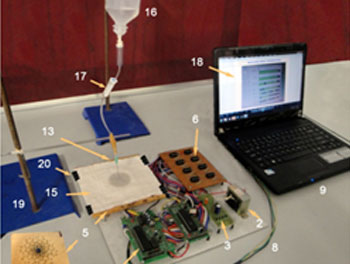

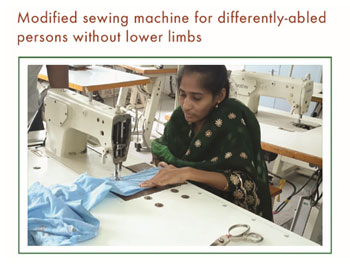

| 1 | DST (Department of Science and Technology) | Instrumentation Development Programme | Dr.D.Raja | Mr.K.Mani Dr.G.Gunasekaran |

Modification of Industrial Grade Sewing Machine for Differently Abled persons | 04.01.2016 | 03.01.2018 |

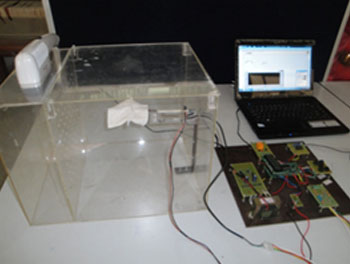

| 2 | IEI (The Institution of Engineers) | R and D Grant in Aid Scheme | Dr.D.Raja | Mrs.S.Priyalatha | Design, development and optimization of a moisture management simulator | 12.07.2016 | 12.01.17 |

| 3 | DST (Department of Science and Technology) | Rural Women Technology Park in Salem | Dr.M.Usha |

Dr.D.Raja, | Sewing machine for differently abled women | 05.01.2017 | 05.01.2020 |

| 4 | DST (Department of Science and Technology) | FIST | Dr.RS.Sabeenian | Dr.D.Raja | Textile Fabric Defects deduction using Intelligence Image Analysis | 2017 | 2022 |

| 5 | AICTE | Staff Development Programme (SDP) | Dr.C.V. Koushik |

Dr.D.Raja | Computer-Integrated Fabric, Apparel Design and Garment Manufacture | 22.11.10 | 04.12.10 |

| 6 | AICTE | Staff Development Programme (SDP) | Dr.C.V. Koushik |

Dr.D.Raja | Advances in Functional Finishes on Textiles and Garments | 21.11.11 | 03.12.11 |

| 7 | IEI (The Institution of Engineers) | R and D Grant in Aid Scheme | Dr.D.Raja | Mr.S.S.Suresh | Design and development of sensor based industrial over lock sewing machine for Orthopedically Handicapped people | 17.06.2019 | 17.06.2021 |

| 8 | AICTE | Modrobs | Dr.D.Raja | - | Modernization of Textile Testing Laboratory | 06.05.2019 | 06.05.2021 |

| 9 | AICTE | Staff Development Programme (STTP) | Dr.D.Raja | - | Advanced apparel Manufacturing | 27.07.2020 | 01.08.2020 |

| 10 | AICTE | Staff Development Programme (SDP) | Dr.D.Raja | - | Future of Fashion | 16.11.2020 | 28.11.2020 |

RESEARCH PUBLICATIONS IN INTERNATIONAL JOURNALS (WITH IMPACT FACTOR)

- Raja, D., Arputharaj, A., Prakash, C., Babu, V. R., & Koushik, C. V. (2010). Study on dyeing behavior of cotton/organic cotton knitted fabrics. Indian Journal of Science and Technology, 3(7), 746-751. (SCI Publication)

- Raja, D., Koushik, C. V., Ramakrishnan, G., Subramaniam, V., & Ramesh Babu, V. (2012). Measuring in-plane liquid spread in fabric using an embedded image processing Technique. Fibres & Textiles in Eastern Europe. 20(4 (93)), 72-76 (SCI Publication)

- Raja, D., Ramakrishnan, G., Babu, V. R., Senthilkumar, M., & Sampath, M. B. (2014). Comparison of different methods to measure the transverse wicking behaviour of fabrics. Journal of Industrial Textiles, 43(3), 366-382. (SCI Publication)

- Raja, D., Ramesh Babu, V., Ramakrishnan, G., & Senthilkumar, M. (2013). Effect of cyclic stress on the transverse wicking behaviour of cotton/lycra knitted fabrics. Journal of the Textile Institute, 104(5), 502-510. (SCI Publication)

- Raja, D., Kouhik, C. V., Ramakrishnan, G., Babu, V. R., & Subramaniam, V. (2012). Horizontal liquid spreading behaviour of hybrid yarn woven fabric using embedded image analysis principle. Indian Journal of Fibres & Textile Research, Vol. 37, December 2012, pp. 381-384 (SCI Publication)

- Raja, D., Babu, V. R., Senthilkumar, M., Ramakrishnan, G., & Kannan, N. (2014). A dynamic sweat transfer tester for analyzing transverse sweat transfer properties of multi-weave structure fabrics. Journal of Industrial Textiles, 44(2), 211-231. (SCI Publication)

- Raja, D., Prakash, C., Ramakrishnan, G., & Koushik, C. V. (2014). Influence of blend ratio and linear density on liquid spreading characteristics of bamboo/cotton-blended yarn knitted fabrics measured by liquid spread tester. The Journal of The Textile Institute, 105(8), 842-849. (SCI Publication)

- Raja, D., Prakash, C., Gunasekaran, G., & Koushik, C. V. (2015). A study on thermal properties of single-jersey knitted fabrics produced from ring and compact folded yarns. The Journal of The Textile Institute, 106(4), 359-365. (SCI Publication)

- Raja, D., Senthilkumar,CM., & Mani, K. (2017). Novel device for evaluating sweat evaporation characteristics of woven and knitted fabrics. Indian Journal of Fibres & Textile Research,Vol 42, No 4, 407-412. (SCI Publication)

- Priyalatha, S., & Raja, D. (2017). Investigation on wicking behavior of the knitted fabrics under different deformation state. The Journal of The Textile Institute, 108(7), 1112-1121. (SCI Publication)

- Mani, K., Raja, D., & Suresh, S.S. (2018). Development of Assistive technology to operate industrial grade sewing machines for differently abled persons. Indian Journal of Fibres & Textile Research, Vol 44, September 2019, pp. 314-320(SCI Publication)

- Raja, D. Priyalatha, S., & Senthilkumar,CM. (2018). A novel device to measure the multi-directional wicking of elastic knitted fabric for active sportswear. Indian Journal of Fibres & Textile Research , Vol. 44, June 2019, pp. 173-179 (SCI Publication)

- Priyalatha, S., & Raja, D. (2018). An Overview on Objective Evaluation of Wicking Property of the Textile Material Used in Sports. Trends in Textile Engineering and Fashion Technology, 2(4). TTEFT.000541.2018. DOI: 10.31031/TTEFT.2018.02.000541 (International journal peer reviewed)

- Priyalatha, S., & Raja, D. (2018). A Multi Directional Wicking Instrument to Measure Wicking Characteristics of Fabrics under Dynamic Movements. Journal of The Institution of Engineers (India): Series E (December 2018) 99(2):209–218 (Scopus Indexed)

- J. Kanimozhi, C. Rajesh Kumar, D. Vasanth Kumar, M. Jesima, Dr. D. Raja, Dr. C. Prakash (2020). Future scope of medical banana fibre: A Review. Journal of Critical Reviews (VOL 7, ISSUE 10, 2020 (Scopus Indexed)

- Vasanth Kumar D, Raja, D. (2020). Influence of Moisture Management Properties on Socks Made from Recycled Polyester, Virgin Cotton and its Blends. Fibres & Textiles in Eastern Europe, 2020, Vol. 28, 4(142), pp 77-81 (SCI Publication)

- D. Vasanth Kumar, D. Raja, and K. V. Kumar, “Effect of Stretching on the Air Permeability of Recycled Polyester/Virgin Cotton and Its Blended Socks,” Journal of Testing and Evaluation https://doi.org/10.1520/JTE20200398 (SCI Publication)

- C. Rajesh Kumar, D. Raja, S. Kubera Sampath Kumarb, and C. Prakash, “Study on Moisture Behavior Properties of Milkweed and Milkweed/Cotton Blended Sanitary Napkins” Journal of Natural Fibers. https://doi.org/10.1080/15440478.2020.1826384 (SCI Publication)

- KR Nandagopal, A Selvakumar and D Raja D, “Effect of Atmospheric Pressure Oxygen Plasma Treatment on Bonding Characteristics of Basalt Fiber Reinforced Concrete”. Fibres and Textiles in Eastern Europe. DOI: 01.3001.0014.6348 (SCI Publication)

- S. Chinnadurai, D. Raja, S. Priyalatha a, S. S. Suresha, and C. Prakash, “An Instrument to Measure the Vertical Wicking of Fabrics by Non-Contact Method Using Color Sensors “ Journal of Natural Fibers https://doi.org/10.1080/15440478.2020.1848731 (SCI Publication)

- C. Rajesh Kumar, C. Prakash, P. Ganesan Mohan, D. Raja and J. Kanimozhi, “Study on Fibre Reinforced Composites Developed by using Recycled Fibres from Garment Cut Waste" International Journal of Clothing Science and Technology (in Press) (SCI Publication)

- RS Sabeenian, ME Paramasivam, T. Shanthi, D.Raja, and C. Prakash, “Robust Fabric Defects Inspection System using Deep Learning Architecture”, Journal of Testing and Evaluation (in Press) (SCI Publication)

RESEARCH PUBLICATIONS IN INTERNATIONAL CONFERENCES

- D. Raja, “Dyeing behavior of fabrics produced from organic and ordinary types of cotton using Natural dyes”, International conference ATNT 2007, 14-16 July 2008, organized by Avinashilingam University for Women, Coimbatore and Texas University USA Coimbatore.

- D. Raja and C.V.Koushik, “Dyeing behavior of fabrics produced from organic and ordinary types of cotton using Reactive Dyes,” 3rd International Textile Conference on Global Textile Vision Strategic Initiatives, 28-30th August 2009, organized by International Textile Educational Consortium & SSM College of Engineering, Komarapalayam,

- D. Raja and C.V.Koushik, “Horizontal wicking behavior of woven fabrics made from ring and compact spun yarns using embedded image analysis principle”, International conference “ATNT 2011”, 15 – 17th December 2011, organized by Kumaraguru College of Technology, Coimbatore,

- D. Raja and C.V.Koushik, “Investigation of Horizontal liquid spread in textiles – A modified method using digital image processing”, International Convention cum Pre-Conference Workshop on Innovations in Engineering and Technology for Sustainable Development, 3rd -5th September 2012, organized by Bannari Amman Institute of Technology, Sathyamangalam.

- R. Ganesh Kumar, D.Raja and G.Gunasekaran, “Electro spinning and its application”, 27th National Convention of Textile Engineers & National Seminar on Design and Manufacture of Technical Textile Materials and Products, 20 – 21st February 2014, organized by The Institution of Engineers (India) Salem Local Centre in Associate with Department of Textile Technology, KSR college of technology.

- S.Priyalatha, D.Raja and G.Gunasekaran, “The effect of vitexnegundo extract treated wound dressing on wound healing”, Indo-Czech International Conference on “Advancements in Specialty Textiles and their Applications in Material Engineering and Medical Sciences, 29-30th April 2014, organized by Department of Textile Technology, Kumaraguru College of Technology, Coimbatore-641049.

- V.Vasanth, D.Raja, M. Ramesh Kumar & G.Gunasekaran, “Development of ballistic protective textile materials using shear thickening fluids”, Indo-Czech International Conference on “Advancements in Specialty Textiles and their Applications in Material Engineering and Medical Sciences, 29-30th April 2014, organized by Department of Textile Technology, Kumaraguru College of Technology, Coimbatore.

- D.Raja and M. Senthilkumar, “Design and development of dynamic transverse wicking measuring device”,Second International Conference on Industrial Textiles - Products, Applications & Prospects, 22 - 23rd August 2014, Department of Textile Technology PSG College of Technology, Coimbatore and HOF University of Applied Sciences, Germany.

- D.Raja, K. Mani, M. Senthilkumar and G.Gunasekaran, “Novel device to measure sweat evaporation characteristics of woven and knitted fabrics”, Second International Conference on Industrial Textiles - Products, Applications & Prospects, 22-23rd august 2014, organized by Department of Textile Technology PSG College of Technology, Coimbatore and HOF University of Applied sciences, Germany.

- D.Raja, D.Vasanth Kumar, S. Priyalatha and G.Gunasekaran, “Single drop water absorbency tester by electrical conductivity principle”, Second International Conference on Industrial Textiles - Products, Applications & Prospects, 22-23rd August 2014, organized by Department of Textile Technology PSG College of Technology, Coimbatore and HOF University of Applied Sciences, Germany.

- S. Priyalatha, K. Mani, D. Raja & G.Gunasekaran, “Challenges faced in adding interlining to the garments”, Second International Conference on Industrial Textiles - Products, Applications & Prospects, 22-23rd August 2014, organized by Department of Textile Technology PSG College of Technology, Coimbatore and HOF University of Applied Sciences, Germany.

- D.Vasanth Kumar, D.Raja and S. Priyalatha, “Evaluation of Sweat Simulation in Socks using a Dynamic Foot Model, International Conference on Trends”, Innovation and Market Potential in Technical Textiles (TMTT-15),12-14 March, 2015, organized by Department of Textile Technology, Bannari Amman Institute of Technology, Sathyamangalam.

- S. Priyalatha, D.Vasanth Kumar and D.Raja, “A Novel Test method to evaluate simultaneous sweat adsorption and evaporation characteristics of fabrics”, International Conference on Trends, Innovation and Market Potential in Technical Textiles (TMTT-15), 12-14 March, 2015, organized by Department of Textile Technology, Bannari Amman Institute of Technology, Sathyamangalam.

- S. Priyalatha, Dr.D.Raja and D.Vasanth Kumar, “Effect of Temperature, Wind Velocity and Liquid Flow Rate on Wetting and Drying of Cotton Knitted fabric”, Fifth International Textile Conference – Emerging Trends in Textile Industry – New innovations, 13-14 August 2015, organized by SSM College of Engineering, The Textile Association (India) – Erode unit, Komarapalayam.

- D.Vasanth Kumar, Dr.D.Raja and S. Priyalatha, “Investigation on comfort properties of Double socks produced by various yarn blends and structures”, Fifth International Textile Conference – Emerging Trends in Textile Industry – New innovations, 13-14 August 2015, organized by SSM College of Engineering, The Textile Association (India) – Erode unit, Komarapalayam.

- S. Priyalatha, Dr. D. Raja, Dr. M. Senthil Kumar and D. Vasanth Kumar, “Investigation on wicking behaviour of the knitted fabric under dynamic state”, 2nd International Conference on Advances in Functional, Smart and Innovative Textiles, (Afsit-2015)”, 10-11 December 2015, organized by PSG Institute of advanced studies, Coimbatore.

- D. Vasanth Kumar, Dr. D. Raja, Dr. M. Senthil Kumar and S. Priyalatha, “Analysis on abrasion resistance of socks using simulated foot model”, 2nd International Conference on Advances In Functional, Smart And Innovative Textiles (Afsit-2015), 10-11 December 2015, organized by PSG institute of advanced studies, Coimbatore.

- Dr.D.Raja, K.Mani, Dr.G.Gunasekaran and S.S.Suresh, “A novel method to control the speed of sewing machine for physically challenged persons”, All India Seminar and Conference on Latest Developments in Technical Textiles and Apparels, 22- 23rdJuly 2016, organized by Bannari Amman Institute of Technology, Sathyamangalam.

- Dr.D.Raja, K.Mani, Dr.G.Gunasekaran and S.S.Suresh, “Development of Automated Sewing Machine for Physically Challenged persons”, Industrial Textiles – Products, Applications and Prospects – Indu Tech 2016, 26 & 27 august 2016, organized by PSG College of Technology, Coimbatore.

- Dr.D.Raja, K.Mani, Dr.G.Gunasekaran and S.S.Suresh, “Design and Development of Modified Sewing Machine for Differently Abled Persons”, National Conference on Industry 4.0, 21 and 22 September 2017, organized by The Institution of Engineers (India) Salem Local Centre and Sona College of Technology.

- Dr.D.Raja, “Applications of Artificial Intelligence in Apparel Industry”, International Virtual Conference on Applied Science, Technology Management and Languages Studies (ASTMLS-2020) on 11th and 12th December 2020, organized by Sona College of Technology, Salem.

- Dr.D.Raja, “Design and Development of Portable Instrument to Measure Fabric Thread Density of Multi-Colour Fabric”, International Virtual Conference on Applied Science, Technology Management and Languages Studies (ASTMLS-2020) on 11th and 12th December 2020, organized by Sona College of Technology, Salem.

- Dr.D.Raja, “Analysis Ageing and Wetting Properties of Basalt Fibres”, International Virtual Conference on Applied Science, Technology Management and Languages Studies (ASTMLS-2020) on 11th and 12th December 2020, organized by Sona College of Technology, Salem.

AICTE STAFF DEVELOPMENT PROGRAME ORGANIZED AS JOINT COORDINATOR

| S.No. | Training Year | Duration | Coordinator | Venue | Subject of Training |

|---|---|---|---|---|---|

| 1. | 2012 | 2 week | Dr.C.V.Koushik | Sona College of Technology, Salem. | AICTE Staff Development Programme - “Advances in Functional Finishes on Textiles and Garments”. |

| 2. | 2010 | 2 week | Dr.C.V.Koushik | Sona College of Technology, Salem. | AICTE Staff Development Programme – “Computer Integrated Fabric/Apparel Design and Garment Manufacture” |

STAFF TRAINING ATTENDED

- Participated & completed successfully AICTE Training and Learning (ATAL) Academy Online FDP on "Research Methodology: Design and Technology" from 02-06-2021 to 06-06-2021 at Banasthali Vidyapith, Rajasthan.

- Two week AICTE FDP on “Future of Fashion: AI, IoT, AR, VR, Robotics, Sensors and Big Data Analytics”organised by Department of Fashion Technology, Sona College of Technology, Salem from Salem from 14.12.2020 – 26.08.2020

- One week AICTE STTP on “Advances in Apparel Manufacturing Technology” organized by Department of Fashion Technology, Sona College of Technology, Salem from 17th August to 22nd August 2020

- Participated & completed successfully AICTE Training and Learning (ATAL) Academy Online FDP on "Design thinking" from 26-10-2020 to 30-10-2020 at Kirori Mal College University of Delhi.

- Participated & completed successfully AICTE Training and Learning (ATAL) Academy Online FDP on "Apparel Design" from 23-11-2020 to 27-11-2020 at Amity School of Fashion Technology, Amity University Uttar Pradesh.

- Four Days Faculty Development Programme on Personnal, Professional and Institutional Well-being” organized by VIT Fashion Institute of Technology (VFIT), VIT Chennai from 7-10-2020 to 10-10-2020

- One week Industrial training on “Quality Control in Apparel”, attended in BM Apparel, Tirupur from 19th to 24th June 2017

- Two Days Faculty Development programme on “STEP-UP Project Management & Leadership Workshop”, held at ECE Conference hall, Sona College of Technology on 20th April & 21st April 2017

- One Day Workshop on “Industrial Engineering and Lean Tools”, held at Mba Conference Hall, Sona College of Technology on 10th July 2016.

- Two Days Workshop on “MOODLE Training”, held at IMB lab, Sona College of Technology on 29th may & 30th May 2016.

- Two Days Workshop on “Data Analytics and Visualization using Excel for Placements”, held at MBA Conference hall, Sona College of Technology on 2nd & 3rd May 2016.

- Two Days Workshop on “Black board Learning Management Training”, held at IMB lab, Sona College of Technology on 26th & 27th April 2016.

- Two Days Workshop on “National Cyber safety & security standards SUBMIT 2015”, organized by PES University, Bangalore, India on 11th & 12th 2015.

- One week Industrial training in “Product Development and Industrial Engineering”, attended in Atlas Exports, Karur from 23rd November to 30th November 2015.

- Two weeks AICTE staff development programme on “Technical Textiles and Garments”, held at Bannari Amman Institute of Technology, Sathiyamangalam, Erode District from 18th May to 30th May 2015.

- Five days Faculty development programme on “Short term course under quality improvement programme – Sizing, Fit & Design of Functional clothing”, held at IIT Delhi, Department of Textile Technology, New Delhi from 3rd to 7th November 2014.

- Six days workshop on “Shop Floor Skills for Apparel Manufacturing – Technology and Application”, held at ECE Conference hall, Sona College of Technology from 21st to 26th July 2014.

- One day workshop on "Intellectual property rights for MSMEs”, organized by Hotel Park Plaza, Salem on 8th October 2014.

- One week Faculty development programme on “Industrial Engineering &Production Planning for Apparel Industry”, held at Department of Fashion Technology, PSG College of Technology, Coimbatore from 10th to 16th June 2014.

- One day workshop on "Energy Optimization and Auditing (ENOPTA) -14", held at Hotel Rain Tree" - 4 Star, Anna Salai, Teynampet, Chennai on 14th June 2014.

- Two weeks AICTE Staff Development Programme on “Biomechanical Engineering Design of Functional Textiles and Clothing”, held at PSG College of Technology, Coimbatore from 7th to 20th November 2013.

- One day workshop on “Denim Processing”, held at Hotel -Le Méridien, Coimbatore on 28th September 2013.

- Two weeks AICTE Staff Development Programme on “Keeping pace with modern textile and garment manufacturing technology”, held at Sona College of Technology, Salem from 3rd to 15th June 2013.

- One day workshop on “Faculty Development Programme on Value Added Teaching”, held at Hotel Cenneys Gateway, Salem on 13th July 2013.

- Five days Faculty development programme on “Apparel production planning and control”, held at Kumaraguru College of Technology on 12 to 15 June 2012.

- Two weeks AICTE Faculty development programme on “Advances in Functional Finishes on Textiles and Garments”, held at Sona College of Technology, Salem from 21st to 3rd December 2012.

- Two days workshop on “Art of journal article and thesis writing,” held at Angel college of engineering and Technology, Tirupur from 9th & 10th January 2012.

- One day workshop on “Medical Textile Training Programme", held at South India Textile Research Association on 2nd March 2012.

- Two weeks AICTE Faculty development programme on “Research Methodology”, held at Sona college of Technology, Salem, from 18th to 30th April 2011.

- Two weeks workshop on “Computer Integrated Fabric/Apparel Design and Garment Manufacture”, held at Sona college of Technology, Salem from 22ndto 3rd December 2010.

- One day workshop on “Conference on Technical Textiles – Indian Possibilities”, held at Hotel Club Mélange, Erode on 26th July 2010.

- Ten days workshop on “Shop Floor Skills for Apparel Manufacturing – Technology and Application”, held at Sona College of Technology, Department of Fashion Technology from 14th-23rd December 2009..

PhD Scholar Guidance (Anna University, Chennai)

| S No | Name | Designation | Research Title | PhD Mode | Status |

|---|---|---|---|---|---|

| 1 | Mrs.S.Priyalatha | Assistant Professor | A New Approach to Evaluate the Moisture Management Properties of Active Sports Wear | Part Time | Completed and Awarded Degree |

| 2 | Mr.D.Vasanth Kumar | Assistant Professor | Investigation on comfort properties of socks produced by novel techniques | Part Time | Completed and Awarded Degree |

| 3 | Mr.K.Mani | Assistant Professor | Design and Development of innovative techniques to operate garment industry sewing machine suitable for physically challenged persons | Part Time | Ongoing |

| 4 | Mr.S.Chinnadurai | Assistant Professor | Measurement of vertical wicking of fabrics using sensors | Part Time | Ongoing |

| 5 | Mr.SS.Suresh | Junior Research Fellow | Wireless wearable electronic gloves to operate industrial grade sewing machine | Full Time | Ongoing |

| 6. | M.Nandhagopal | Assistant Professor | Technical Textile Area | Part Time | Ongoing |

| 7. | C. Rajesh Kumar | Assistant Professor | Design and Development of Sanitary napkin with antibacterial finish | Part Time | Ongoing |

LECTURE DELIVERED AS RESOURCE PERSON

- Delivered lecture in International Webinar (28.07.2020) on "Application of IoT and AI in Apparel Industry" at Isfahan University of Technology, Faculty of Textile Engineering, IRAN

- Delivered lecture on “Application of AI in Apparel industry” as Resource person in AICTE Faculty Development Programme (14.12.2020 ) on “AI, IoT, AR, VR, Robotics, Sensors and Big Data Analytics” organised by Department of Fashion Technology, Sona College of Technology, Salem from Salem

- Delivered lecture on “Application of IOT in Apparel industry” As Resource person in AICTE STTP (17.08.2020) on “Advances in Apparel Manufacturing Technology” organized by Department of Fashion Technology, Sona College of Technology, Salem.

- As Resource person of an National level Webinar on “Textile and Fashion” on 18th June, 2020 delivered lecture on the topic “3D Garmenting and Fit Analysis”.PSG Arts and Science College

- Delivered guest lecture as Resource person in online webinar on the topic “Application of IoT and AI in Apparel Industry” on 20.07.2020 by Department of Apparel Technology, PSG Polytechnic college, Coimbatore

- Delivered guest lecture as Resource person in online webinar “ Testing and Quality parameters of PPE Body Coverall for Covid -19” on 27th August, 2020, Department of Textile Technology, University College of Technology, Osmania University, Hyderabad.

- Delivered lecture in Awareness program on Higher studies in Engineering Discipline –(UNICEF Initiative -Integrated child protection programe ) –Venue: Edapadi govt school, date: 02.02.2015 (Full day)

- Delivered lecture as Resource person in AICTE Faculty Development Programme on “Technical Textiles and Garments” organised by Bannarai Amman Institute of Technology”. Topic delivered: Importance of transverse wicking and its evaluation methods.

- As member of academic advisory committee, Technical advice given to IIHT, Salem to buy new set of sewing machine for garment construction lab

- As BOS member, Attended BOS meeting in Kumaraguru College of Technology on 28.03.15 for BTech FT curriculum modification discussion.

COORDINATOR AND RESOURCE PERSON FOR THE FOLLOWING PROGRAMME

- Industry executive Trining Programme in the area of Apparel Quality Control for KMD Clothing executives, Salem

- Tie - Dye and Block printing course for unemployed people– 3 week Programme.

RESOURCE PERSON FOR CSRI COURSE

- Handled courses in centre for social responsibility initiatives – Fashion Designing and Garment making (Resource person for: Printing area classes) from 23rd to 26th March 2015.

- Handled courses in centre for social responsibility initiatives – Fashion Designing and Garment making (resource person for:Printing area classes) from 28/11/16 to 2/12/16

MEMBERSHIP OF THE PROFESSIONAL BODIES

- Life Member in ISTE - LM 95682

- Corporate Member in the Institution of Engineers (India) – AM130636-5

- Life Member in Textile Association of India (TAI).

PATENT GRANTED

S No |

Patent No |

Title |

|---|---|---|

| 1 | 330753 | Design and development of dynamic sweat transfer tester for multi weave fabric |

PATENT APPLIED

| Sno | File no | Title |

|---|---|---|

| 1. | 4542/CHE/2014 | Modification of Industrial-Grade Sewing Machine to make it User-friendly for Differently-abled Persons |

| 2. | 4541/CHE/2014 | Design and Development of Cyclic Stress Instrument to measure the Dynamic Liquid Spread Behaviour of Knitted Fabrics |

| 3. | E-1/48565/2018 CHE |

An Assistive Electronic Device To Operate Sewing Machines Thereof |

| 4. | E-1/39333/2019 CHE |

Wearable Haptic Hand-Device for Differently-Abled People to Operate Industrial Sewing Machines |

AWARD RECEIVED/HONOR

- All India Council for Technical Education (AICTE) on April 11, 2021 gave away the Lilavati Award 2020 for creating a better society for women in India Read more

- As a department overall coordinator for data collection of AICTE CII award, received AICTE CII award three times for the year 2016, 2018, 2019 and 2020 Also we won AICTE CII Mentor (2020-2023)

- AICTE CII 2016 award for best industry linked Engineering institution in India under chemical engineering category (BTech Fashion Technology) Read more

- AICTE CII 2018 award for best industry linked Engineering institution in India under chemical engineering category (BTech Fashion Technology) Read more

- AICTE CII 2019 award for best industry linked Engineering institution in India under chemical engineering category (BTech Fashion Technology) Read more

- AICTE CII 2020 award for best industry linked Engineering institution in India under chemical engineering category (BTech Fashion Technology),Also Won AICTE CII Mentor Award Read more

- Precitex Award Winner for Best outgoing student in the year 1993-94 Read more

- Received Appreciation certificate from Mr. KR.Nagarajan, Founder and CEO of RAMRAJ COTTON, Tirupur for the commendable R and D work on Developing sewing machine for differently abled people Read more

- Received Award of excellence certificate for the outstanding service as zonal review committee member for the papers of IET'16 Innovation of Engineering & Technology Read more

- Guided student project received III price in Techknow14 - AIMO award organized by Anna University in the year of 2014. Read more

- Received staff award for producing 100% results Read more

- Received staff award for publishing article in reputed international journals with impact factor. Read more

- Anna University Recognized Supervisor (Ref.No: 23.05.02) to guide PhD and M.S. (By Research) Scholars in Textile Technology area. Read more

- As department placement coordinator (FT Department) - Achieved 100% placement for the last three batches. Read more

- Book Reviewer in Elsevier publication

- Number of Papers Reviewed: Around 60 Papers of International peer reviewed Journals

REVIEWER - LIST OF JOURNALS

- SAGE Publications - Textile Research Journal

- SAGE Publications - Journal of Industrial Textiles

- The Textile Association (India) - Journal of the Textile Association

- Taylor & Francis – The Journal of Textile Institute

- Springer Publications – The Institution of Engineers (India)

- NISCAIR - Indian Journal of Fibres and Textile Research

CITATION INDICES

- Citations : 138

- h-index : 7 Read more

CONSULTANCY WORK

- COORDINATOR AND RESOURCE PERSON FOR THE FOLLOWING PROGRAMME

- Industry executive Trining Programme in the area of Apparel Quality Control for KMD Clothing executives, Salem.

- Tie - Dye and Block printing course for unemployed people– 3 week programme, organized through community polytechnic & Sona CSIR.

- Skill development programme – Smart Garment Operator.

COMPLETED RESEARCH WORK

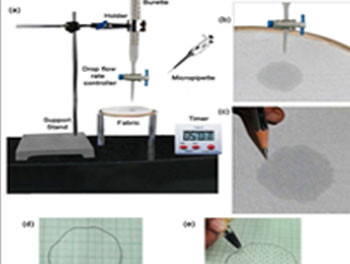

| 1. Novel method to measure the water spreading area on the fabric | |

|---|---|

Objectives:

|

|

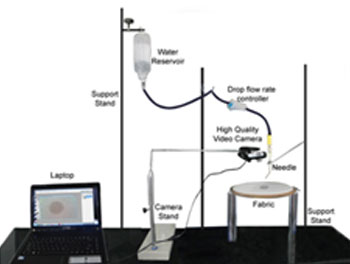

| 2. New technique used to measure water spreading area on the fabric by image analysis method | |

Objectives:

|

|

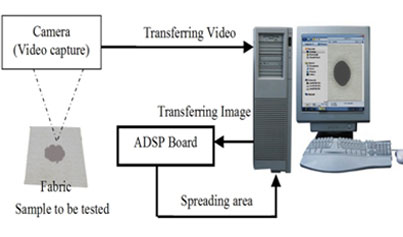

| 3. Novel test method used to measure water spreading area on the fabric by embedded image analysis technique using digital signal processor. | |

Objectives:

|

|

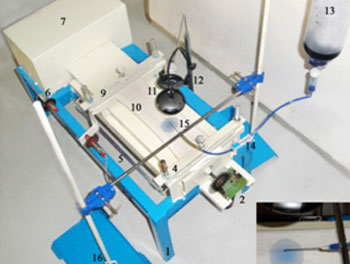

| 4. Design and development of new instrument used tostudy the effect of cyclic stress on the transverse wicking behaviour of cotton/lycra knitted fabrics | |

Objectives:

|

|

| 5. Design and development of new instrument used tostudy the effect of cyclic loading on the transverse wicking behaviour of cotton/lycra knitted fabrics | |

Objectives:

|

|

| 6. Design and Development of sweat transfer tester used to study the dynamic liquid spread beahaviour of multi weave fabric | |

Objectives:

|

|

| 7. Design and development of sweat evaporation device used to evaluate the sweat evaporation characteristics. | |

Objectives:

|

|

| 8. Modification of Industrial-Grade Sewing Machine to make it User-friendly for Differently-abled Persons | |

Objectives:

|

|